The Fast Fit beam clamp is an off the shelf engineered clamping solution to connect two steel sections together without the need for onsite drilling or welding. 5/8″ Type CF

Fast Fit Type BCFF16

Product Description

The Fast Fit is an off the shelf engineered clamping solution to connect two steel sections together without the need for onsite drilling or welding. All you need to secure two sections together comes in one box. The system comprises a frame which wraps around the edges of the sections and slides into place to provide a position for the clamps to be secured.

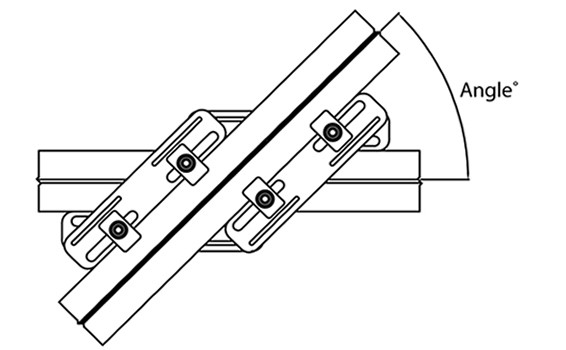

The system allows for varying angles that can be easily achieved by sliding the beams relative to each other.

The Fast Fit system delivers a guaranteed connection every time without the need for on-site testing or relying on the skills of the installer. No removal of the protective coatings on the existing steel or holes is required to make a connection. All that is required to complete a connections are simple hand tools and semi-skilled labor.

Features, Advantages and Benefits of the Fast Fit

| Features | Advantages | Benefits |

|---|---|---|

| No drilling or welding to existing structure | No on-site power required | Reduced installation time and ot need to relocate cables, hoses etc. |

| Clamps directly to the existing structure | No damage to corrosion protection and no weakening of the steel | Flexibility and reduced on-site installation time |

| No heat or sparks generated | No hot work permit is necessary | Reduction in installation cost and administration time |

| No additional safety considerations | Safe for use in hazardous conditions | Peace of mind that the connection can be made without any hazards created |

| Installation by semi-skilled labor | No need for specialist skills or equipment | Reduction in per hour labor costs |

| Easy re-alignment of steel members | Eliminates remedial work due to steel miss alignment | Reduction in labor costs and provides on site flexibility |

| Tested at a third party test facility | Third party tested for use in tensile and frictional applications | Confidence that the connection will perform as stated in the literature |

| Electro Galvanized Finish | Corrosion protection is provided as standard meaning no post touch up or finish | Reduction in installation time and confidence in the finish |

| Suits a wide range of steel sections | A one stop shop for most connections | Reduced sourcing costs for users |

| Guaranteed loading and factor of safety | No on-site testing required for reliance on the skill of the installer | Reduction in installation time and peace of mind that every connection will perform as stated |

| Flush steel to steel connection | No location plate or spacers required | Saves time on re-design due to height level changes |

Technical Information

| Product Code | Price | Bolt Dia. A | Bolt Grade | Bolt Length | Overall Size | Flange Thickness | Flange Width | Torque (ft. lbs) | Tensile SWL (lbs.) | Friction SWL (lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|

| BCFF16 | ???? | 5/8″ | 8.8 | 5″ | 13-3/4″ x 13-3/4″ | 1/4″ – 1″ | 2-1/2″ – 7-1/2″ | 110 | 4763 | 1142 |

The above loading data has a 5:1 Factor of Safety

Achievable Angles

The Fast Fit System is designed to allow sections of different widths to be connected at varying angles. The table below provides information on what angles can be achieved.

| Flange Width | Top Steel Section | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.5″ | 3.0″ | 3.5″ | 4.0″ | 4.5″ | 5.0″ | 5.5″ | 6.0″ | 6.5″ | 7.0″ | 7.5″ | ||

| Bottom Steel Section | 2.5″ | 45 | 45 | 50 | 50 | 50 | 55 | 55 | 60 | 65 | 70 | 75 |

| 3.0″ | 45 | 45 | 50 | 50 | 50 | 55 | 55 | 60 | 65 | 70 | 75 | |

| 3.5″ | 50 | 50 | 50 | 50 | 55 | 55 | 55 | 55 | 65 | 70 | 75 | |

| 4.0″ | 50 | 50 | 50 | 50 | 55 | 55 | 55 | 55 | 65 | 70 | 75 | |

| 4.5″ | 50 | 50 | 50 | 50 | 50 | 55 | 55 | 55 | 65 | 70 | 75 | |

| 5.0″ | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 65 | 70 | 75 | |

| 5.5″ | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 60 | 65 | 70 | 75 | |

| 6.0″ | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 65 | 65 | 70 | 75 | |

| 6.5″ | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 70 | 75 | |

| 7.0″ | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 75 | 75 | |

| 7.5″ | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 80 | |